Sunrise

The World’s Major Home Lifestyle Provider

Sunrise Textile

The World’s Major Home Lifestyle Provider

Zhangjiagang Sunrise Textile Co., LTD is a global textile and apparel manufacturer. We export mostly knit fleece home textile items and apparel to the United States, Europe and other markets. Established in 1999, Sunrise Textile has highly vertically integrated operations including knitting, fabric dyeing, fabric printing, finishing, and final processing such as setting and anti-pilling. Today, the company is one of the world’s major home lifestyle product providers.

Founded July 8, 1999

CEO & Founder Ray Zhu

Business Variety Raised Fabrics Home Textile

Number of Employees 280 at headquarters and overseas 4,500 at factories

Revenue US $240 Million

History

2019

20th Anniversary

On July 8th, 2019, Sunrise Group celebrates the 20th Anniversary in Zhangjiagang.

2019

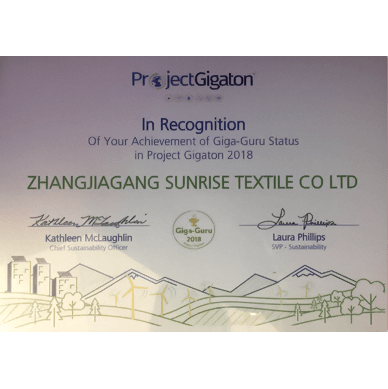

Certifications

Sunrise received Walmart’s award in recognition of Sunrise’s achievement of Giga-Guru in Project Gigaton 2018.

2019

Award

Sunrise is awarded “ Supplier of The Year 2018, Bedding” by Walmart

1999

Zhangjiagang Sunrise Knitting Co., Ltd was founded.

Zhangjiagang Sunrise Knitting Co., Ltd was founded and changed to the name of Zhangjiagang Sunrise Knitting Investment and Development Co., Ltd. in 2013.

CEO's Message

Dear Customers,

Since its establishment in 1999, Zhangjiagang Sunrise Textile Co., LTD has maintained consistent growth through specialized raised fabric home and textile, apparel exporting and stable internal management. Sunrise Textile has become the top raised fabric manufacturer in China, and a major home lifestyle provider worldwide. Currently, we have two marketing channels in the United States, five production bases in China, over 280 people in our headquarters and overseas, and 4,500 people working in manufacturing locations. With 2019 marking the twentieth year since the establishment of Zhangjiagang Sunrise Textile Co., our company will continue to be an innovative and integrated lifestyle home product provider by transitioning from OEM manufacturing to an ODM specialized company.

On behalf of the 4,800 employees at Zhangjiagang Sunrise Textile Co., Ltd., I sincerely thank you for your support and interest.

Ray Zhu

CEO & Founder

Since its establishment in 1999, Zhangjiagang Sunrise Textile Co., LTD has maintained consistent growth through specialized raised fabric home and textile, apparel exporting and stable internal management. Sunrise Textile has become the top raised fabric manufacturer in China, and a major home lifestyle provider worldwide. Currently, we have two marketing channels in the United States, five production bases in China, over 280 people in our headquarters and overseas, and 4,500 people working in manufacturing locations. With 2019 marking the twentieth year since the establishment of Zhangjiagang Sunrise Textile Co., our company will continue to be an innovative and integrated lifestyle home product provider by transitioning from OEM manufacturing to an ODM specialized company.

On behalf of the 4,800 employees at Zhangjiagang Sunrise Textile Co., Ltd., I sincerely thank you for your support and interest.

Ray Zhu

CEO & Founder

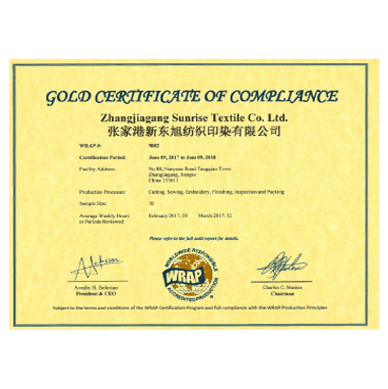

Certifications

Zhangjiagang Sunrise was founded on the philosophy there is always a way to make

things better. We are committed to consistently improving our products and our

company. With every stitch we bring quality, excellence and value to your life.

things better. We are committed to consistently improving our products and our

company. With every stitch we bring quality, excellence and value to your life.

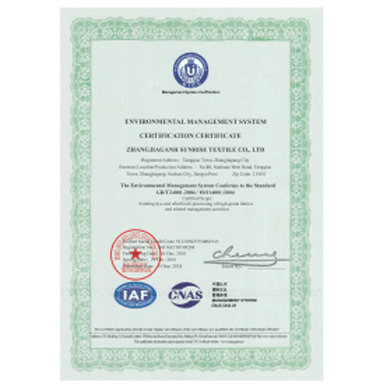

Zhangjiagang Sunrise was founded on the philosophy there is always a way to makethings better. We are committed to consistently improving our products and our company. With every stitch we bring quality, excellence and value to your life.

Corporate Social Responsibility

Corporate Social Responsibility

- January 30, 2018, Sunrise Labor Union gave financial assistance to employees with total 20,000 RMB.

- In 2017, Sunrise Employee Foundation donated total 9,000 RMB to deserving workers.

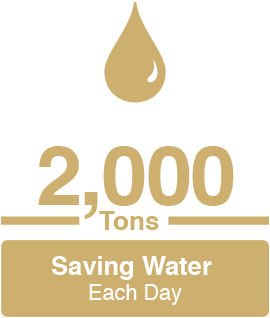

Environmental Protection

- Coal-fired boilers were replaced with natural gas boilers, to reduce emissions.

- Printing machines, polishing machines and fixing machines are updated by using natural gas power source.

- Fixing machines were updated by adding hood purification equipment, which reduce the waste gas to meet emission standard.

- Added up computerized flow meter to control daily wastewater effluent within the limits.

- Our company has passed ISO system certification of ISO50001 energy management, ISO14001 environment management and ISO9001 quality management since 2014, and received renewal certification every year from 2016.

ISO50001

Energy Management System Certification

Green Earth

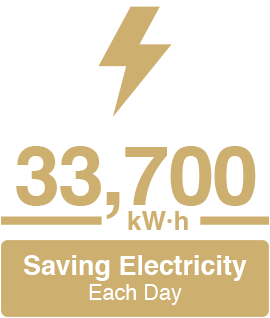

- 6MV Solar Panel is set up in Shuyang factory in March of 2019 to annually save 7,300,000 kW·h.

- Completed the replacement of all filament to LED lamps in 2018.

- Built pre-treatment waste water pools in 2018 to daily pre-treat waste water saving 3,000-5,000 tons.

- Added frequency transformers to all equipment in 2013 and variable frequency air compressors in 2017 to end of 2018, annually saving 5,000,000 kW·h.

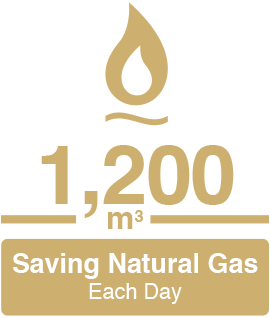

- Installed thermal insulation material to dyeing tanks to annually save 5,000 tons of steam and 120,000m3 natural gas.

- Recycled heat wind from drying machines and natural gas boilers to use on heater through tubes in 2009 to annually save 300 tons of steam and 300,000m3 natural gas.

- Recycled water from radiators to cooling water pools to cooling dyeing tanks, saving 2,000 tons of water per day.